|

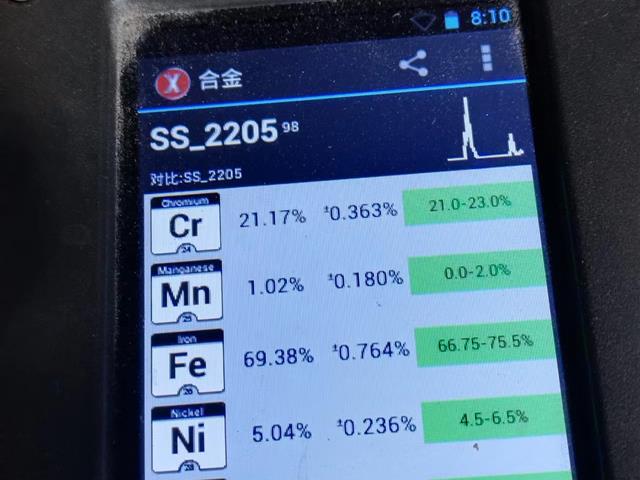

Grade |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

N |

|

S32205 |

≤0.03 |

≤2.00 |

≤0.03 |

≤0.02 |

≤1.00 |

4.50~6.50 |

22.00~23.00 |

3.00-3.50 |

0.14-0.20 |

Chemical Composition

Mechanical Properties

|

Grade |

Tensile Strength ksi(MPa) |

Yield Strength ksi (MPa) |

Elongation (%) |

Hardness HBW |

Hardness HRC |

|

S32205 |

≥95(655) |

≥65(450) |

≥25 |

≤290 |

≤30 |

Applications

- Systems that use seawater

- Pumps and valves for seawater

- Vessels for chemical processing, pipework, and heat exchangers

- Scrubbers for fgd

- Digesters for pulp mills and bleach washers

- Food processing machinery

- Pipeline in the oil field

Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

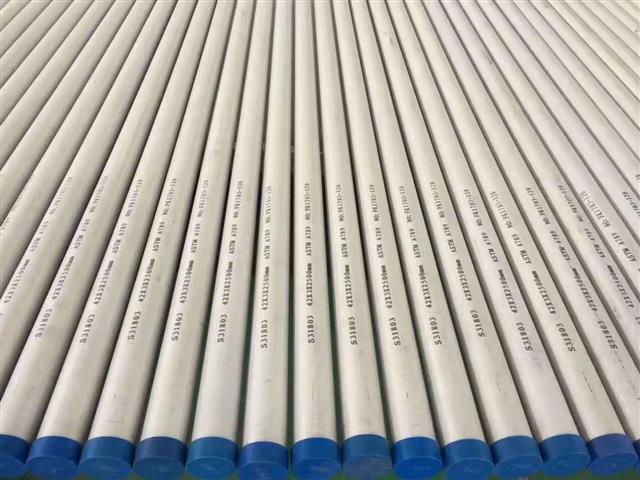

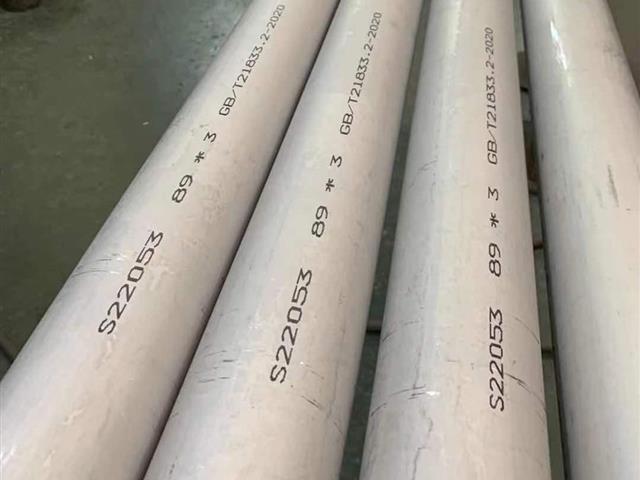

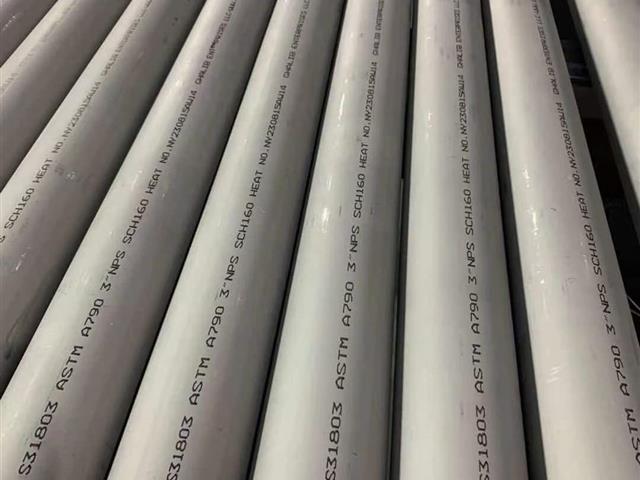

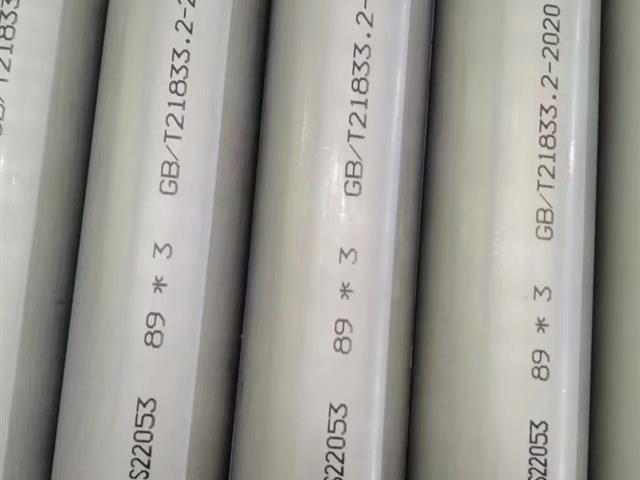

Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM A790 S32205 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

Material Summary

Duplex S32205 are the most common duplex grades in the market. They have very good resistance to localized corrosion and stress corrosion cracking in combination with high mechanical strength. They are widely used in oil & gas, hydro power, pressure vessels, pulp & paper, structural components and chemical tankers. The alloys are not intended to be used at temperatures above 300°C due to embrittlement..

S32205 are characterized by:

High resistance to stress corrosion cracking in halide containing environments.

High resistance to pitting and crevice corrosion.

High resistance to general corrosion.

High mechanical strength.

High resistance to erosion corrosion and corrosion fatigue.

Standard download

ASTMA789 Seamless and Welded Ferritic Austenitic Stainless Steel Tubing for General Service

ASTMA790 Seamless and Welded FerriticAustenitic Stainless Steel Pipe