ASTMB163 ASTMB423 Incoloy 825/Nickel Alloy 825/ N08825/ 2.4858/ NA16/NCF825 Seamless Nickel Alloy Steel Pipe

① STANDARD: ASTM B163 ASTMB423 Seamless Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 Chemical Composition

|

Grade |

Ni |

Cr |

Fe |

Mn |

C |

Cu |

Si |

S |

Al |

Ti |

Mo |

|

Alloy 825 |

38.00-46.00 |

19.50-23.50 |

≥22.00 |

≤1.00 |

≤0.05 |

1.50-3.00 |

≤0.50 |

≤0.03 |

≤0.20 |

0.06 -1.20 |

2.50-3.50 |

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 Mechanical Properties

Grade

Condition

Tensile Strength ksi(MPa)

Yield Strength ksi(MPa)

Elongation(%)

N08825

Annealed

≥85(586)

≥35(241)

≥30

N08825

Hot finished annealed

≥75(517)

≥25(172)

≥30

N08825

Cold-worked annealed

≥85(586)

≥35(241)

≥30

N08825

Hot-forming quality

-

-

-

|

Grade |

Condition |

Tensile Strength ksi(MPa) |

Yield Strength ksi(MPa) |

Elongation(%) |

|

N08825 |

Annealed |

≥85(586) |

≥35(241) |

≥30 |

|

N08825 |

Hot finished annealed |

≥75(517) |

≥25(172) |

≥30 |

|

N08825 |

Cold-worked annealed |

≥85(586) |

≥35(241) |

≥30 |

|

N08825 |

Hot-forming quality |

- |

- |

- |

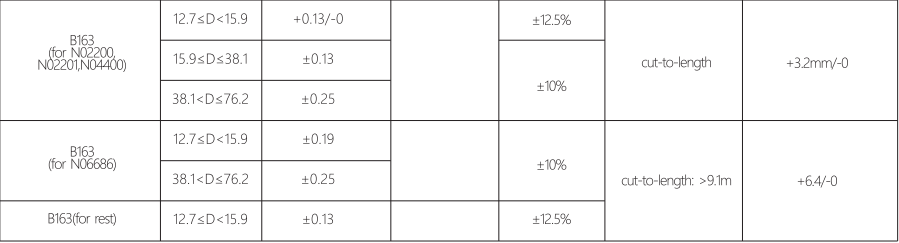

The ASTM B163 Nickel alloy seamless tube and pipe tolerance

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 APPLICATIONS

Alloy 825 is widely used in oil and gas applications. Other uses include chemical process equipment, exhaust systems, and power generation. CRA offers specialty alloy 825 seamless pipe & tube for use in multiple industries and applications, including:

- Chemical Processing:

- Incoloy 825 is widely employed in chemical processing equipment due to its resistance to general corrosion, pitting, and crevice corrosion.

- It is used in sulphuric acid piping and vessels, phosphoric acid evaporators, and other chemical process components.

- Pollution Control:

- The alloy is utilized in pollution control systems, especially in environments with sulphur-containing flue gases.

- Its corrosion resistance ensures efficient operation in such applications.

- Oil and Gas Recovery:

- Incoloy 825 is found in oil and gas production facilities, where it withstands harsh conditions.

- It is used in offshore applications, including marine components and seawater handling.

- Nuclear Fuel Reprocessing:

- The alloy’s resistance to corrosion makes it suitable for nuclear fuel reprocessing equipment.

- It ensures safety and longevity in handling radioactive materials.

- Acid Production and Pickling Operations:

- Incoloy 825 is employed in acid production facilities and pickling tanks.

- Its stability in oxidizing and reducing conditions is advantageous.

- Other Applications:

- Heat exchangers, condensers, and general engineering components benefit from Incoloy 825.

- It is also used in food processing equipment, paper mills, and automotive/aerospace components

Remember that Incoloy 825’s broad usefulness stems from its corrosion resistance under diverse conditions.

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ..............

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

One of our Services--Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM B163 UNS N08825 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 Material Summary

In the oil and gas industry, the two most important nickel alloys are Inconel 625 and Incoloy 825. lncoloy 825 is an austenitic nickel-iron-chromium-molybdenum-copper alloy containing high levels of chromium, nickel, copper, and molybdenum to provide high levels of corrosion resistance to both moderately oxidizing and moderately reducing environments. This balance of alloying elements grants this alloy exceptional resistance to both chloride stress corrosion cracking, as well as crevice corrosion and general corrosion. It is the high level of nickel in combination with the amount of molybdenum and copper in this nickel alloy produces substantially improved corrosion resistance in a corrosive environment such as reducing environments compared to stainless steel. The addition of titanium in this alloy also helps to stabilize the alloy against intergranular corrosion. Chloride stress corrosion cracking is a type of localized intergranular corrosion on materials that are put under tensile strength, in high temperatures and in an environment that includes oxygen and chloride ions such as seawater.

As an austenitic, nickel alloy, the material is ductile over a wide range of temperatures from cryogenic to well more than 1000 °F (538 °C). Fabricability is typical for a nickel alloy, with the material readily formable and weldable by a variety of techniques.

Related Products

ASTMB161 ASTMB163 Nickel 200 Alloy (UNS N02200)/2.4066 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B161/ ASTM B163/ASME SB161/ASME AB163② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

ASTMB407 UNS N08120 Seamless Nickel Alloy Steel Tube

ASTMB407 UNS N08120 Seamless Nickel Alloy Steel Pipe

Hastelloy C-4 2.4610 NiMo16Cr16Ti N06455 Seamless Stainless Steel Pipe

Alloy C-4 / 2.4610 is an austenitic low-carbon nickel-molybdenum-chromium alloy① STANDARD: ASTM B161/ ASTM B163/ ASTM B167/ ASTM B444/ ASTM B622 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.