ASTMB622 ASTMB829 Hastelloy B2/UNS N10665/2.4617 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B622/ASME SB622 for seamless , ASTM B619 for welded ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

UNS N10665/2.4617/Hastelloy B2 Chemical Composition

|

Grade |

Ni |

Cr |

Mo |

Fe |

C |

Si |

Co |

Mn |

P |

S |

|

UNS N10665 |

Balance |

≤1.00 |

26.00-30.00 |

≤2.00 |

≤0.02 |

≤0.10 |

≤1.00 |

≤1.00 |

0.040 |

0.030 |

UNS N10665/2.4617/Hastelloy B2 Mechanical Properties

|

Grade |

Tensile Strength ksi(MPa) |

Yield Strength ksi(MPa) |

Elongation (%) |

|

UNS N10665 |

≥110(760) |

≥51(350) |

≥40 |

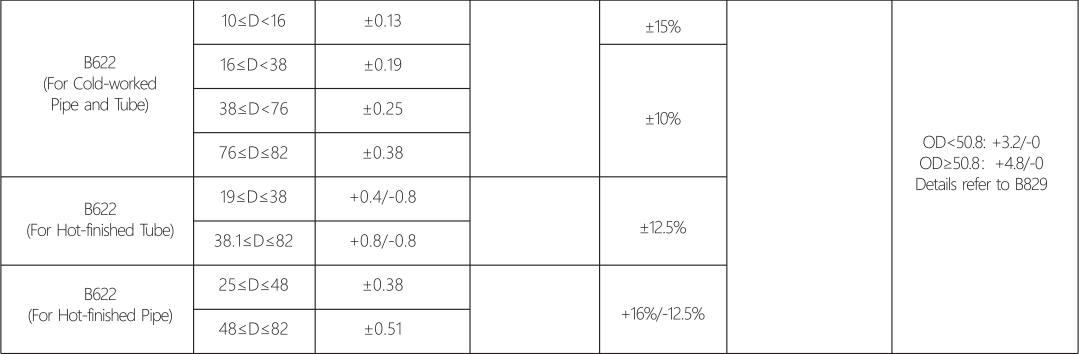

the ASTM B622 Nickel alloy seamless tube and pipe tolerance

UNS N10665/2.4617/Hastelloy B2 Applications

Hastelloy B2, also known as UNS N10665, is a nickel-molybdenum alloy with high levels of chromium and molybdenum. Its exceptional properties make it suitable for various industrial applications. Let’s explore how it is used in different industries:

- Chemical Processing:

- Hastelloy B2 is widely employed in chemical processing equipment due to its excellent corrosion resistance against a wide range of organic and inorganic acids.

- It finds applications in reactors, heat exchangers, and other components exposed to aggressive chemical environments.

- Oil and Gas Industry:

- In the oil and gas sector, Hastelloy B2 is used in sweetening units, sour gas wells, and offshore platforms where corrosion resistance is essential.

- Its ability to withstand harsh conditions makes it valuable in these applications.

- Pharmaceutical Industry:

- Hastelloy B2 is employed in pharmaceutical equipment due to its corrosion resistance and formability.

- It ensures product purity and safety in critical processes.

- Power Generation:

- The alloy is used in power plants for components like de-aerating heaters.

- Its good oxidation resistance at high temperatures contributes to efficient operation.

- Marine Engineering:

- In marine applications, Hastelloy B2 is suitable for marine fixtures, bimetal contacts, and gasoline and freshwater tanks.

- Its corrosion resistance ensures longevity in saltwater environments.

Remember that Hastelloy B2’s versatility and superior properties make it an ideal choice for demanding environments across various industries.

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ........

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

One of our Services--Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM B622 UNS N10665 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

UNS N10665/2.4617/Hastelloy B2 Material Summary

Alloy B2 Pipes and Tubes is a solid solution strengthened, nickel-molybdenum alloy, typically used in extreme reducing conditions. UNS N10665 Pipes and Tubes has significantly lower carbon, silicon and iron compared to its’ predecessor, Alloy B (UNS N10001), making the alloy less susceptible to decreased corrosion resistance in the weld zone, in the as-welded condition.

Alloy B2 is a nickel-molybdenum alloy with significant resistance to reducing environments, such as hydrogen chloride gas and sulphuric, acetic and phosphoric acids. Hastelloy B2 provides resistance to pure sulphuric acid and a number of non-oxidizing acids. The alloy should not be used in oxidizing media or where oxidizing contaminants are available in reducing media. Premature failure may occur if alloy B2 is used where ferric iron, cupric ion and free chlorides are present.

With a high nickel content, Hastelloy B2 is immune to chloride-induced stress corrosion cracking.

Related Products

ASTMB167 ASTMB829 Inconel601/UNS N06601/ 2.4851/NCF 601 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B167/ASME SB167/ASTM B829 ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

ASTMB622 Hastelloy C22 /UNS N06022/ 2.4602 Seamless Nickel Alloy Steel Pipe

① STANDARD: ASTM B622/ASME SB 622 for seamless ASTM B619/ASME SB 619 for welded, ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Hastelloy C-4 2.4610 NiMo16Cr16Ti N06455 Seamless Stainless Steel Pipe

Alloy C-4 / 2.4610 is an austenitic low-carbon nickel-molybdenum-chromium alloy① STANDARD: ASTM B161/ ASTM B163/ ASTM B167/ ASTM B444/ ASTM B622 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

ASTMB407 Incoloy800/ 800H/800HT(UNS N08800/N 08810/N 08811) Seamless Nickel Alloy Steel Pipe

① STANDARD: ASTM B407 ...② OD RANGE : 6-508MM③ THICKNESS RANGE: 1-45 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.