ASTMB161 ASTMB163 Nickel 200 Alloy (UNS N02200)/2.4066 Seamless Nickel Alloy Steel Pipe

① STANDARD: ASTM B161/ ASTM B163/ASME SB161/ASME AB163② OD RANGE : 6-457MM③ THICKNESS RANGE: 1-35 MM

Nickel 200 Alloy (UNS N02200)/2.4066 Chemical Composition

|

Grade |

Ni |

Cu |

Fe |

Mn |

C |

Si |

S |

|

UNS N02200 |

≥99.00 |

≤0.25 |

≤0.40 |

≤0.35 |

≤0.015 |

≤0.35 |

≤0.01 |

|

UNS N02201 |

≥99.00 |

≤0.25 |

≤0.40 |

≤0.35 |

≤0.02 |

≤0.35 |

≤0.01 |

Nickel 200 Alloy (UNS N02200)/2.4066 Mechanical Properties

|

Grade |

Condition |

Tensile Strength |

Yield Strength |

Elongation(%) |

|

N02201 |

Annealed |

≥50(345)ksi(MPa) |

≥12(83)ksi(MPa) |

≥40 |

|

N02201 |

Stress-relieved |

≥60(414)ksi(MPa) |

≥30(207)ksi(MPa) |

≥15 |

|

N02201 OD≤127MM |

Annealed |

≥50000(380)psi(MPa) |

≥12000(80)psi(MPa) |

≥35 |

|

N02201 OD>127MM |

Annealed |

≥50000(345)psi(MPa) |

≥10000(70)psi(MPa) |

≥40 |

|

N02201 |

Stress-relieved |

≥60000(415)psi(MPa) |

≥30000(205)psi(MPa) |

≥15 |

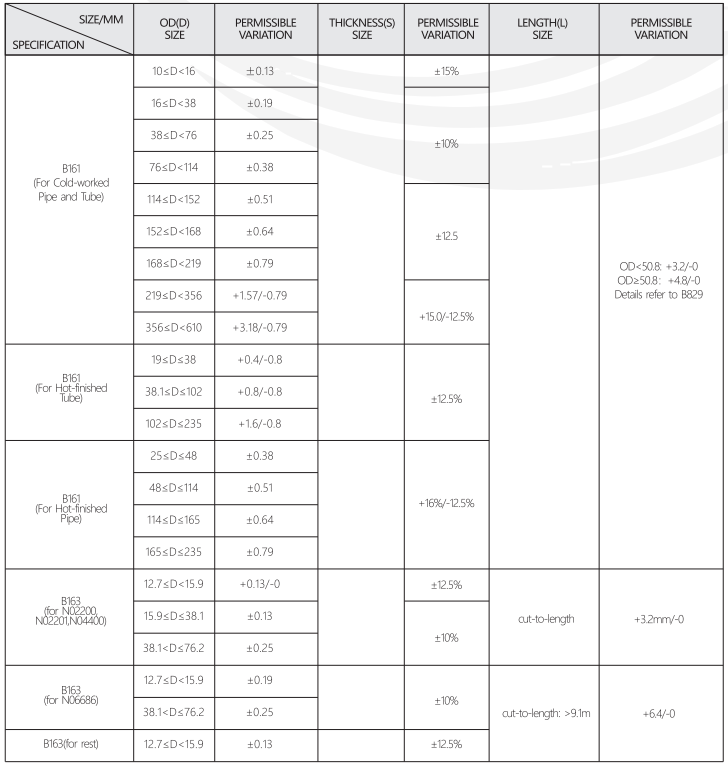

the ASTM B161 ASTMB163 Nickel alloy seamless tube and pipe tolerance

Nickel 200 Alloy (UNS N02200)/2.4066 Applications

Nickel Alloy 200 Pipe is widely used in various industries such as

Chemical processing, Aerospace, Marine, and Oil and Gas.

Heat exchangers, Reactors, Pipelines, and other high-temperature applications.

Electrical components and is ideal for use in corrosive environments.

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

One of our Services--vMarking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM B161 UNS N02200 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

Nickel 200 Alloy (UNS N02200)/2.4066 Material Summary

Nickel Alloy 200 pipe prevents attacks from

media and alkalis as well as sulfuric, hydrochloric, and hydrofluoric acids.

While the majority of this alloy is composed of nickel, trace amounts of other

elements include a maximum of 0.40% Fe, 0.35% Mn, 0.35% Si, 0.25% Cu, and 0.15%

C. As a result, Nickel Alloy 200 features excellent magnetic and

magnetostrictive properties, high thermal and electrical conductivity, low gas

content, and low vapor pressure.

Conventional fabrication methods can be used on Nickel Alloy 200 pipe. It can

be welded, brazed, or soldered using common methods. Despite its high strength,

Nickel Alloy 200 is typically hot rolled, cold formed, and successfully

machined as long as industry accepted procedures are used. Nickel Alloy 200, Commercially

Pure Nickel, and Low Alloy Nickel offer a purity level that many industries

require in their products. For structural applications, Nickel 200 alloy

ensures long term integrity thanks to its resistance to a variety of

corrosives. In food handling, it provides excellent abrasion and corrosion

resistance, helping to maintain sterile and hygienic processing. Nickel Alloy

200's purity features protection from caustic alkalis and other reducing

chemicals.

The material complies with various

international standards and exhibits good physical properties such as high

strength, good ductility, and toughness. It also has a low coefficient of

thermal expansion, making it ideal for use in high-temperature applications.

Nickel Alloy 200 Pipe has several advantages over other materials such as its

excellent corrosion resistance, cost-effectiveness, and ease of fabrication.

Related Products

ASTMB622 UNS N08031/1.4562/Alloy31/X1NiCrMoCu32-28-7 Seamles Nickel Alloy Steel Pipe

① STANDARD: ASTM B622/ ASTM B829 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

ASTMB622 ASTMB829 Hastelloy B3/Alloy B3/ UNS N10675/2.4600 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B622/ ASTM B829 ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

ASTMB622 ASTMB829 Hastelloy B3/Alloy B3/ UNS N10675/2.4600 Seamless Nickel Alloy Steel Pipe

① STANDARD: ASTM B622/ ASTM B829 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

ASTMB161 ASTMB163 Nickel 200 Alloy (UNS N02200)/2.4066 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B161/ ASTM B163/ASME SB161/ASME AB163② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.