|

Grade |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

N |

|

S32205 |

≤0.03 |

≤2.00 |

≤0.03 |

≤0.02 |

≤1.00 |

4.50~6.50 |

22.00~23.00 |

3.00-3.50 |

0.14-0.20 |

UNS S32205 SAF2205 S22253 022Cr23Ni5Mo3N Chemical Composition

UNS S32205 SAF2205 S22253 022Cr23Ni5Mo3N Mechanical Properties

|

Grade |

Tensile Strength ksi(MPa) |

Yield Strength ksi (MPa) |

Elongation (%) |

Hardness HBW |

Hardness HRC |

|

S32205 |

≥95(655) |

≥65(450) |

≥25 |

≤290 |

≤30 |

UNS S32205 SAF2205 S22253 022Cr23Ni5Mo3N Applications

-

UNS S32205, also known as Duplex 2205, is a duplex stainless steel alloy with excellent properties. Let’s explore its applications in various industries:

- Seawater Systems:

- UNS S32205 is commonly used in seawater systems due to its high resistance to pitting and crevice corrosion.

- It ensures durability in marine environments.

- Chemical Process Equipment:

- In chemical processing, this alloy finds applications in pressure vessels, high-pressure storage tanks, and high-pressure pipelines.

- Its corrosion resistance and strength make it valuable in handling aggressive chemicals.

- Heat Exchangers and Fittings:

- Heat exchangers, fittings, and other components benefit from UNS S32205’s good weldability.

- It is used in the chemical processing industry.

- FGD Scrubber Systems:

- Flue gas desulfurization (FGD) scrubber systems utilize UNS S32205.

- Its resistance to corrosive gases ensures efficient pollution control.

- Pulp Mill Digesters and Bleach Washers:

- In the paper industry, this alloy is employed in pulp mill digesters and bleach washers.

- Its mechanical strength and corrosion resistance contribute to reliable performance.

- Food Process Equipment:

- UNS S32205 is suitable for food processing equipment.

- Its acid resistance ensures product purity and safety.

- Oil Field Piping:

- In the oil and gas industry, this alloy is used for oil field piping.

- Its properties withstand harsh conditions in oil exploration and production.

Remember that UNS S32205’s combination of corrosion resistance, strength, and weldability makes it a versatile material across various industrial applications.

S32205 Key Features and Advantages

Exceptional High Strength: It offers a yield strength that is approximately double that of conventional austenitic stainless steels like 316L, allowing for the design of lighter, thinner-walled components.

Superior Stress Corrosion Cracking (SCC) Resistance: The duplex structure provides outstanding resistance to chloride SCC, a common failure point for standard austenitic stainless steels (like 304L/316L) in warm, chloride-rich environments.

Excellent Localized Corrosion Resistance: The high content of Chromium (≈22% ),Molybdenum (≈3% ), and Nitrogen (N) provides superior resistance to pitting andcrevice corrosion, particularly effective in marine or brackish water environments.

Good Weldability: The material exhibits good weldability, though filler metal (like ER2209) is typically required, and it retains excellent corrosion properties in the as-welded condition.

High Energy Absorption/Toughness: It retains good toughness, including down to temperatures as low as −50∘C (−58∘F).

Low Thermal Expansion: Its coefficient of thermal expansion is lower than that of austenitic stainless steels, which helps reduce thermal stress and distortion in complex structures.

UNS S32205 SAF2205 S22253 022Cr23Ni5Mo3N Material Summary

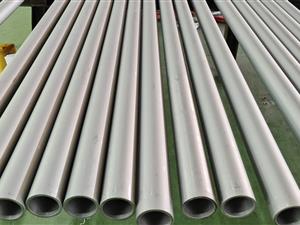

Stainless Steel S32205 Seamless Tube is a high-performance, precision-engineered hollow cylinder manufactured from a solid billet, resulting in a product completely free of any welded seams. This construction is crucial for maximizing structural integrity, ensuring uniform corrosion resistance, and achieving the tight tolerances required in critical applications like heat exchangers and instrumentation lines.

TheS32205 designation (often referred to as Duplex 2205 or W.Nr. 1.4462) identifies a Duplex Stainless Steel—meaning its microstructure is balanced, consisting of roughly 50% Ferrite and 50% Austenite phases. This unique dual-phase composition is the key to its exceptional properties, effectively combining the favorable qualities of both stainless steel families: the high strength andchloride stress corrosion cracking (SCC) resistance of ferritic steels with the general corrosion resistance andfabricability of austenitic steels.

The S32205 specification is the enhanced version of the earlier S31803 grade, featuring tighter controls on the chromium, molybdenum, and critically, the nitrogen content to guarantee superior corrosion resistance performance.

Standard download

ASTMA789 Seamless and Welded Ferritic Austenitic Stainless Steel Tubing for General Service

ASTMA790 Seamless and Welded FerriticAustenitic Stainless Steel Pipe