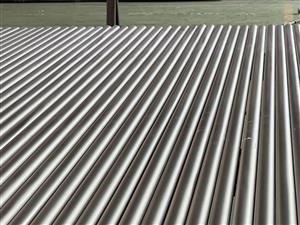

Stainless steel heat exchanger tube is a component used to transfer heat between two or more fluids without mixing them. XTD is a reliable manufacturer of stainless steel heat exchanger tubes based in SONGYANG , China. We specialize in producing high-quality stainless steel heat exchanger tubes that meet 213 ASTM international standards. They are used in various industrial applications such as chemical processing, power generation, HVAC, and food processing.

SA-213/SA-213M Specification for seamless Ferritic Alloy steel boiler, Superheater and heat exchanger tubes

Delivery Condition: Normalized and Tempered

Inspections and Tests Performed: Chemical Composition Inspection, Mechanical

Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring,

Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,

No-destructive Test, Hydrostatic Test.

Surface treatment: Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

Inner packing: Caps on two ends of every pipe

Package: bare packing/bundle packing/wooden carton packing.

|

Size Tolerance |

||||

|

Tube Kinds |

SA213 OD(D) |

SA213 Thickness(S) |

||

|

OD(mm) |

OD Tolerance(mm) |

OD(mm) |

Thickness Tolerance(mm) |

|

|

Hot Rolled |

≤101.6 |

+0.4~-0.8 |

76~168.3 |

+28%~0 |

|

>101.6~168.3 |

+0.4~-1.2 |

|||

|

Cold Drawn |

<25.4 |

0.1 |

≤38.1 |

+20%~0 |

|

25.4~38.1 |

0.15 |

|||

|

>38.1~<50.8 |

0.2 |

>38.1 |

+22%~0 |

|

|

50.8~<63.5 |

0.25 |

|||

|

63.5~<76.2 |

0.3 |

|||

|

76.2~101.6 |

0.38 |

|||

|

>101.6~190.5 |

+0.38~-0.64 |

|||

|

>190.5~228.6 |

+0.38~-1.14 |

|||

|

Grade |

Tensile Strength,Min., ksi[MPa] |

Yield Strength,Min., ksi[MPa] |

Elongation |

|

T12 |

60 [415] |

32 [220] |

30 |

|

T23 |

74 [510] |

58 [400] |

20 |

|

T91 |

85 [585] |

60 [415] |

20 |

|

T92 |

90 [620] |

64 [440] |

20 |

|

T122 |

90 [620] |

58 [400] |

20 |

|

18Cr-2Mo |

60 [415] |

40 [275] |

20 |

|

NOTES: |

|

|

|

|

(1) When standard round 2 in. or 50 mm gage length or smaller proportionally sized specimens with gage length equal to 4D (4 |

|||

|

times the diameter) is used, the minimum elongation shall be 22% for all ferritic grades except 18Cr-2Mo, T23 and T91. |

|||

|

(2) For longitudinal strip tests, a deduction from the basic minimum |

|||