ASTMB407 Incoloy800/ 800H/800HT(UNS N08800/N 08810/N 08811) Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B407 ...② OD RANGE : 6-257MM③ THICKNESS RANGE: 1-35 MM

Alloy800/ 800H/800HT(UNS N08800/N 08810/N 08811) Chemical Composition

Grade

Ni

Cu

Fe

Mn

C

Si

S

Cr

Al

Ti

P

Other

Alloy 800

30.00-35.00

≤0.75

≥39.50

≤1.50

≤0.10

≤1.00

≤0.015

19.00-23.00

0.15-0.60

0.15-0.60

0.045

-

Alloy 800H

30.00-34.00

≤0.50

39.50

≤1.50

≤0.10

≤1.00

≤0.015

19.00-22.00

-

0.75-1.50

-

-

Alloy800HT

30.00-35.00

≤0.75

39.50

≤1.50

0.05-0.10

≤1.00

≤0.015

19.00-23.00

0.15-0.60

0.25-0.60

0.045

AL+Ti=0.85-1.20

| Grade | Ni | Cu | Fe | Mn | C | Si | S | Cr | Al | Ti | P | Other |

| Alloy 800 | 30.00-35.00 | ≤0.75 | ≥39.50 | ≤1.50 | ≤0.10 | ≤1.00 | ≤0.015 | 19.00-23.00 | 0.15-0.60 | 0.15-0.60 | 0.045 | - |

| Alloy 800H | 30.00-34.00 | ≤0.50 | 39.50 | ≤1.50 | ≤0.10 | ≤1.00 | ≤0.015 | 19.00-22.00 | - | 0.75-1.50 | - | - |

| Alloy800HT | 30.00-35.00 | ≤0.75 | 39.50 | ≤1.50 | 0.05-0.10 | ≤1.00 | ≤0.015 | 19.00-23.00 | 0.15-0.60 | 0.25-0.60 | 0.045 | AL+Ti=0.85-1.20 |

Alloy800/ 800H/800HT(UNS N08800/N 08810/N 08811) Mechanical Properties

Material

Tensile Strength

Yield Strength

Elongation

ksi

MPa

ksi

MPa

%

Alloy 800

75

517

30

207

30

Alloy 800H

65

448

25

172

30

Alloy 800HT

65

448

25

172

30

|

Material |

Tensile Strength |

Yield Strength |

Elongation |

|||

|

ksi |

MPa |

ksi |

MPa |

% |

||

|

Alloy 800 |

75 |

517 |

30 |

207 |

30 |

|

|

Alloy 800H |

65 |

448 |

25 |

172 |

30 |

|

|

Alloy 800HT |

65 |

448 |

25 |

172 |

30 |

|

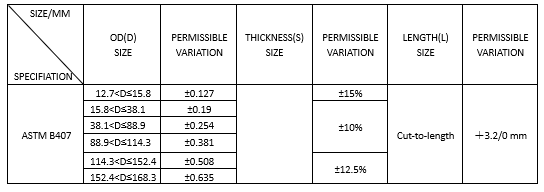

the ASTM B407 Nickel alloy seamless tube and pipe tolerance

Alloy800/ 800H/800HT(UNS N08800/N 08810/N 08811) Applications

-

-

-

-

- Heat Treatment and Power Generation:

- Alloy 800/800H/800HT® is frequently used in applications that involve long-term exposure to elevated temperatures.

- It finds use in heat treatment equipment, superheater and reheater tubing, headers, pigtails, outlet manifolds, and sheathing for heating elements1.

- Chemical and Petrochemical Processing:

- In chemical plants, these alloys are employed for components exposed to corrosive environments.

- Their resistance to oxidation, carburization, and elevated temperature corrosion is crucial for chemical processing equipment2.

- Nuclear Industry:

- Alloy 800/800H/800HT® is used in nuclear power plants for steam generators and nuclear reactor parts.

- Its ability to withstand high temperatures and resist corrosion is essential in this industry3.

- Paper Pulp Industry:

- Heat-treating equipment such as baskets, trays, and fixtures often employ Incoloy 800H/HT.

- These alloys contribute to maintaining equipment integrity in paper mills4.

Remember that Alloy 800/ 800H/800HT®’s properties make them suitable for environments where resistance to oxidation, carburization, and other types of elevated temperature corrosion is required.

-

-

-

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

One of our Services--Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM B407 UNS N08800 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

Alloy800/ 800H/800HT(UNS N08800/N 08810/N 08811) Material Summary

Alloy 800 - The 800 series of alloy (Incoloy 800, 800H and 800HT) are nickel-iron-chromium superalloys that have excellent properties of high temperature strength and resistance to oxidation, carburization and other types of high temperature corrosion. Alloy 800, 800H and 800HT are used in various applications from furnace components, petrochemical furnace cracker tubes to sheathing for electrical heating elements.

Incoloy 800 Pipe is one of the widely used pipes in the production of high strength equipment. The material has higher resistance against carburization and oxidation. This makes the material special for applications that require the carburization resistant and corrosion resistant properties. Alloy 800H Seamless Pipe is cold drawn and has high creep resistance and rupture resistance as well. The material is made ductile by the addition of nickel in the composition at the same time it is pretty much corrosion resistant because of the addition of chromium into the composition. The Ni 800 HT Hot Finished Pipe remains austenitic because of the nickel component. The high temperature resistance of the ASTM B407 UNS N08811 Incoloy 800HT Pipe makes it applicable in heat treating equipment and fixtures. The Incoloy 800 Seamless Pipe has higher precision in its dimensions.

This nature is important for narrow fixtures that require high precision. Application of Alloy 800 Pipe is seen in steam generator tubes, sheathing of electric heating elements, paper and pulp industries and in the petroleum processing plants. The most used shape is the Incoloy Alloy 800 Round Pipe whereas the other shapes are used as well. Depending on the application requirement, there could be other shapes such as the 800H Incoloy Square Pipe. Square pipes are usually used for applications that require structural strength. The Incoloy Alloy 800HT Clad Pipe is used for cladding of other material pipes. Since the material can withstand high temperatures, it could be used to prevent exposure of other softer material to heat. The Incoloy 800HT Pipe is used especially in the chemical and petrochemical processing, with the process equipment in ethylene and variations. The Incoloy 800H Pipe could be used interchangeably and these are both solution annealed. They have high creep resistance and rupture resistance as a result.

Related Products

ASTMB407 UNS N08120 Seamless Nickel Alloy Steel Tube

ASTMB161 B163 Nickel 201 Alloy (UNS N02201)/2.4068 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B161/ ASTM B163/ASME SB161/ASME AB163② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

ASTMB622 UNS N08031/1.4562/Alloy31/X1NiCrMoCu32-28-7 Seamles Nickel Alloy Steel Tube

① STANDARD: ASTM B622/ ASTM B829 ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

ASTMB983 Inconel718 Alloy718 UNSN07718 2.4668 H41690 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B983...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.