ASTMB622 HastelloyC276/AlloyC-276/N10276/2.4819/Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B622 B619...② OD RANGE : 6-257MM③ THICKNESS RANGE: 1-35 MM

AlloyC-276/HastelloyC276/N10276/2.4819/Inconel 276 Chemical Composition

Grade

Ni

Cr

Mo

Fe

W

C

Si

Co

Mn

V

P

S

HASTELLOY C276

Balance

14.50-16.50

15.00-17.00

4.00-7.00

3.00-4.50

≤0.01

≤0.08

≤2.50

≤1.00

≤0.35

≤0.04

≤0.03

|

Grade |

Ni |

Cr |

Mo |

Fe |

W |

C |

Si |

Co |

Mn |

V |

P |

S |

|

HASTELLOY C276 |

Balance |

14.50-16.50 |

15.00-17.00 |

4.00-7.00 |

3.00-4.50 |

≤0.01 |

≤0.08 |

≤2.50 |

≤1.00 |

≤0.35 |

≤0.04 |

≤0.03 |

AlloyC-276/HastelloyC276/N10276/2.4819/Inconel 276 Mechanical Properties

Grade

Tensile Strength ksi(MPa)

Yield Strength ksi(MPa)

Elongation (%)

HASTELLOY C276

≥100(690)

≥41(283)

≥40

|

Grade |

Tensile Strength ksi(MPa) |

Yield Strength ksi(MPa) |

Elongation (%) |

|

HASTELLOY C276 |

≥100(690) |

≥41(283) |

≥40 |

AlloyC-276/HastelloyC276/N10276/2.4819/Inconel 276 Applications

-

-

- Chemical Processing:

- Hastelloy C-276 is widely used in chemical reactors, heat exchangers, and other equipment.

- Its resistance to aggressive chemicals (such as sulfuric acid, hydrochloric acid, and chlorine) makes it ideal for this industry1.

- Metal Processing and Machining:

- The alloy finds applications in metal processing due to its ability to withstand chemical reactions.

- It provides ease of forming and welding, making it suitable for various machining processes.

- Power Generation:

- In power plants, Hastelloy C-276 is used for components like gas scrubbers and heat exchangers.

- Its oxidation resistance at high temperatures (up to 1100 ºC) is crucial for power generation applications.

- Pharmaceutical Industry:

- Hastelloy C-276 is employed in pharmaceutical equipment, including tanks, pipes, and valves.

- Its corrosion resistance ensures product purity and safety.

- Pollution Control:

- Flue gas desulfurization systems utilize Hastelloy C-276 flanges to resist sulfuric acid formation.

- These flanges are also used in water and wastewater treatment facilities.

- Other Applications:

- Food processing, marine engineering, and petrochemical industries benefit from Hastelloy C-276.

- Its versatility and reliability make it a preferred choice for critical environments.

Remember that Hastelloy C-276’s properties make it suitable for a wide range of applications where corrosion resistance and durability are essential.

-

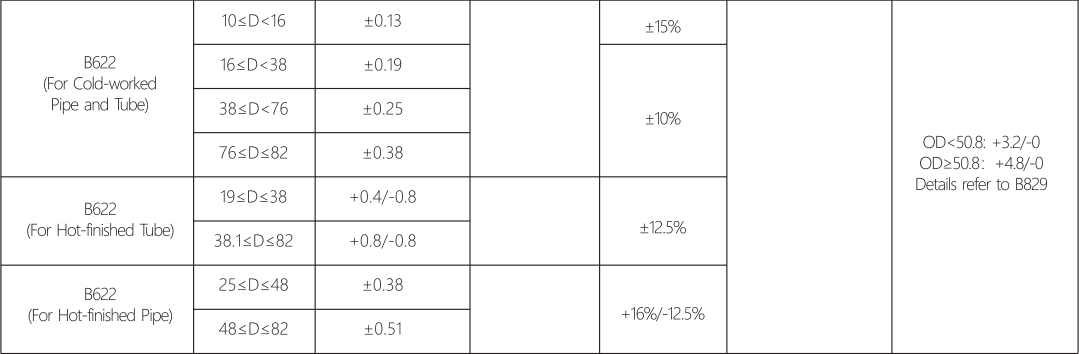

the ASTM B622 Nickel alloy seamless tube and pipe tolerance

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

One of our Services--Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM B622 UNS N10276 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

AlloyC-276/HastelloyC276/N10276/2.4819/Inconel 276 Material Summary

Inconel C-276 is a high-performance nickel-chromium-molybdenum alloy, renowned for its exceptional resistance to a wide range of corrosive environments. It’s particularly well-suited for applications that involve severe chemical exposure, high temperatures, and aggressive environments.

Key Characteristics:

- Corrosion Resistance: Inconel C-276 is highly resistant to a variety of corrosive conditions, including:

- Oxidizing: Good resistance to oxidizing environments up to moderate temperatures.

- Reducing: Excellent performance in reducing environments.

- Pitting and Crevice Corrosion: Strong resistance to pitting and crevice corrosion, making it ideal for use in seawater and other aggressive environments.

- Temperature Resistance: The alloy maintains its strength and resistance to oxidation at temperatures up to approximately 1000°C (1832°F). This makes it suitable for high-temperature applications.

- Mechanical Properties:

- Tensile Strength: Good tensile strength at both room and elevated temperatures.

- Ductility: Excellent ductility and toughness, even in cryogenic conditions.

- Applications:

- Chemical Processing: Equipment and components in chemical processing and petrochemical industries.

- Flue Gas Desulfurization: Parts exposed to sulfur compounds in flue gas desulfurization units.

- Marine: Components used in marine environments and offshore structures.

- Power Generation: Parts in power generation plants, especially those exposed to corrosive conditions.

Inconel C-276 is favored in industries where high performance in harsh environments is critical. Its ability to withstand both oxidative and reductive corrosion, along with high-temperature stability, makes it a reliable choice for challenging applications.

Related Products

ASTMB161 B163 Nickel 201 Alloy (UNS N02201)/2.4068 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B161/ ASTM B163/ASME SB161/ASME AB163② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

ASTMB622 Hastelloy C22 /UNS N06022/ 2.4602 Seamless Nickel Alloy Steel Pipe

① STANDARD: ASTM B622/ASME SB 622 for seamless ASTM B619/ASME SB 619 for welded, ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

ASTMB983 Incoloy 925 Alloy925 UNS N09925 2.4858 Seamless Nickel Alloy Steel Pipe

① STANDARD: ASTM B983...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

ASTMB983 Inconel718 Alloy718 UNSN07718 2.4668 H41690 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B983...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.