Hastelloy B3 Seamless Nickel Alloy Steel Tube

Hastelloy B3 Seamless Nickel Alloy Steel Tube is a high-performance nickel-molybdenum alloy tube specifically designed to offer excellent resistance to hydrochloric acid and other strongly reducing chemicals. Known for their enhanced thermal stability and improved fabricability, these tubes are widely used in harsh chemical environments. ① STANDARD: ASTM B622/ ASTM B829 ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Hastelloy B3/Alloy B3/ UNS N10675/2.4600 Chemical Composition

Grade

Ni

Cr

Mo

Fe

W

C

Si

Co

Mn

V

P

Ti

Cu

Al

Zr

Cb(Nb)

Ta

Ni+Mo

N10675

≥65.00

1.00-3.00

27.00-32.00

1.00-3.00

≤3.00

≤0.01

≤0.10

≤3.00

≤3.00

≤0.20

≤0.03

≤0.20

≤0.20

≤0.50

≤0.10

≤0.20

≤0.20

94.00-98.00

|

Grade |

Ni |

Cr |

Mo |

Fe |

W |

C |

Si |

Co |

Mn |

V |

P |

Ti |

Cu |

Al |

Zr |

Cb(Nb) |

Ta |

Ni+Mo |

|

N10675 |

≥65.00 |

1.00-3.00 |

27.00-32.00 |

1.00-3.00 |

≤3.00 |

≤0.01 |

≤0.10 |

≤3.00 |

≤3.00 |

≤0.20 |

≤0.03 |

≤0.20 |

≤0.20 |

≤0.50 |

≤0.10 |

≤0.20 |

≤0.20 |

94.00-98.00 |

Hastelloy B3/Alloy B3/ UNS N10675/2.4600 Mechanical Properties

Grade

Tensile Strength ksi(MPa)

Yield Strength ksi(MPa)

Elongation(%)

N10675

≥110(760)

≥(350)

≥40

|

Grade |

Tensile Strength ksi(MPa) |

Yield Strength ksi(MPa) |

Elongation(%) |

|

N10675 |

≥110(760) |

≥(350) |

≥40 |

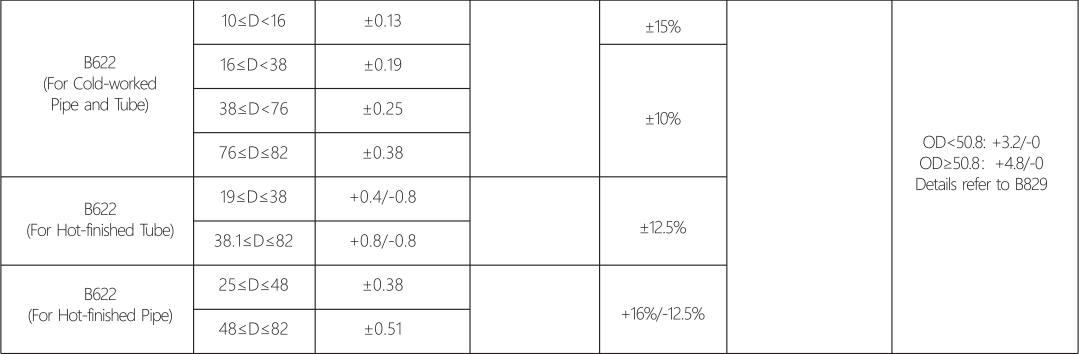

the ASTM B622 Nickel alloy seamless tube and pipe tolerance

Hastelloy B3/Alloy B3/ UNS N10675/2.4600 Applications

Hastelloy B3 is a nickel-molybdenum alloy that is highly resistant to corrosion by reducing atmospheres, such as hydrogen chloride gas and sulfuric acid. It contains a higher concentration of chromium and molybdenum, making it more resistant to pitting and crevice corrosion in chloride-containing environments.

- - Chemical processing and production of pharmaceuticals, pesticides, and synthetic fibers

- - Production of acetic acid, vinyl chloride monomer, and hydrogen fluoride

- - Gas scrubbers, heat exchangers, and evaporators in marine environments

- - Equipment for flue gas desulfurization systems

- - Nickel wetted parts in chlorine dioxide bleach plants

- - Digesters and bleach plants in paper and pulp industries

- - Scrubbers and cooling towers in power plants.

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ........

Hastelloy B3/Alloy B3/ UNS N10675/2.4600 Material Summary

HASTELLOY B3 alloy (UNS N10675) is an excellent resistance alloy to hydrochloric acid at all concentrations and temperatures. It also withstands sulfuric, acetic, formic and phosphoric acids, and other nonoxidizing media. B3 alloy has a special chemistry designed to achieve a level of thermal stability greatly superior to that of its predecessors, e.g. HASTELLOY B2 alloy. B3 alloy has excellent resistance to pitting corrosion, to stress-corrosion cracking and to knife-line and heat-affected zone attack.

Hastelloy B3 is a nickel-based alloy with excellent corrosion resistance and resistance to stress corrosion cracking. Its main components include nickel, molybdenum, iron, chromium and other elements. Hastelloy B3 seamless pipe is a common form of Hastelloy B-3 material, which is widely used in chemical industry, aerospace, marine engineering and other fields.

Related Products

UNS N08031 Seamles Nickel Alloy Steel Tube

UNS N08031 Seamles Nickel Alloy Steel Tube are high-performance nickel-based alloy tubes known for their exceptional corrosion resistance, strength and durability in demanding environments. ① STANDARD: ASTM B622/ ASTM B829 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Inconel 601 Seamless Nickel Alloy Steel Pipe

Inconel 601 Seamless Nickel Alloy Steel Pipe is made from a high-performance nickel-chromium-iron alloy, specially designed to offer outstanding oxidation resistance and mechanical strength at elevated temperatures. This makes them an ideal choice for demanding industrial environments. ① STANDARD: ASTM B167/ASME SB167/ASTM B829 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Hastelloy B3 Seamless Nickel Alloy Steel Tube

Hastelloy B3 Seamless Nickel Alloy Steel Tube is a high-performance nickel-molybdenum alloy tube specifically designed to offer excellent resistance to hydrochloric acid and other strongly reducing chemicals. Known for their enhanced thermal stability and improved fabricability, these tubes are widely used in harsh chemical environments. ① STANDARD: ASTM B622/ ASTM B829 ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Seamless Inconel 600 Nickel Alloy Tube

Seamless Inconel 600 Nickel Alloy Tube is a high-performance nickel-chromium alloy tube known for their excellent resistance to corrosion, oxidation, and high temperatures. ① STANDARD: ASTM B163/ASME SB163,ASTM B167 / ASME SB167....② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.