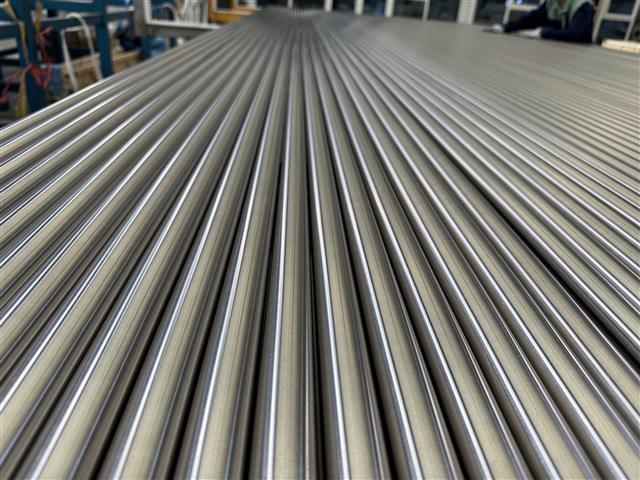

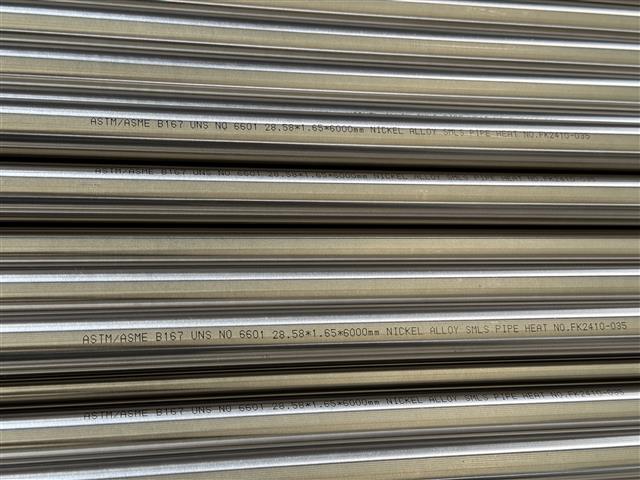

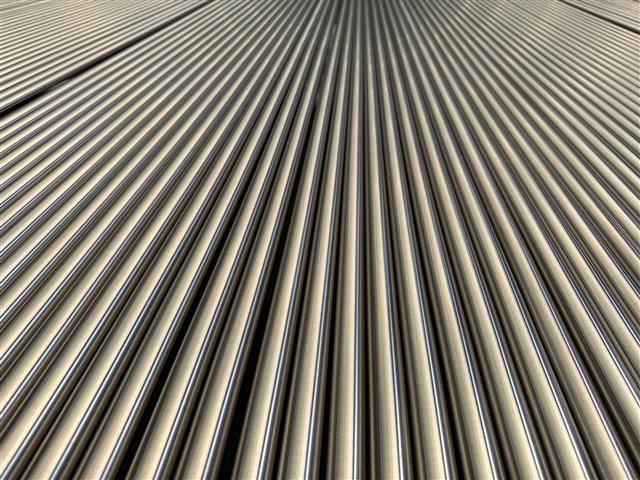

Inconel 601

nickel-chromium-iron alloy is a general-purpose engineering material for

applications that require resistance to heat and corrosion. The outstanding

characteristic of Inconel 601 is its resistance to high-temperature oxidation.

The alloy also has good resistance to aqueous corrosion, has high mechanical

strength, and is readily formed, machined, and welded.

The most important property of Inconel 601

is resistance to oxidation at very high temperatures up to 1250C. Even under

severe conditions such as, cyclical heating and cooling. This is possible due

to Inconel 601 having a tightly adherent oxide layer which is resistant against

spalling.

1,High-Temperature

Properties: Inconel 601 exhibits remarkable

resistance to high-temperature oxidation. This makes it suitable for

applications in thermal processing, chemical processing, and power

generation.

2,Aqueous

Corrosion Resistance: The alloy also has good

resistance to aqueous corrosion, making it useful in various industrial

settings.

3,Mechanical

Strength: Inconel 601 has high mechanical

strength, allowing it to withstand demanding conditions.

4,Metallurgical

Stability: Its face-centered-cubic solid solution

structure, combined with substantial chromium content, contributes to its

stability.