Material Summary

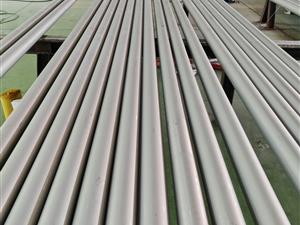

Stainless steel heat exchanger tube is generally used for boiler, heat exchanger, and condenser, standards are A249 welded tube and A213 seamless tube, 304 / 304L, 316 / 316L, 310S, 2205, S31803 stainless steel grades, annealing pickling or bright annealing condition.

Stainless steel tube has high temperate resistance and corrosion resistance, are used for heat transfer processes and are mostly applied in heating, cooling, condensation and evaporation of liquids, gases and steam.

We offer a range of alloys that deliver high strength, thermal conductivity, and corrosion-resistant properties to ensure optimum performance in extreme condition

Heat Exchanger Applications

Heat exchanger is a device used to transfer heat between a solid object and a fluid, or between two or more fluids at different temperatures, transfer heating from higher temperature fluid to lower temperature object to make fluid temperature to specified requirement, for stainless steel grades, there are shell and tube heat exchanger, plate heat exchangers, plate and shell heat exchanger and other heat exchanger, tube heat exchanger consists of a number of tubes inside bundle and sheet, widely used in many industries.

- Space Heating

- Refrigeration

- Air Conditioning

- Power Stations

- Chemical Plants

- Petrochemical Plants

- Petroleum Refineries

- Natural-Gas Processing

- Wine And Beer Making

|

American Standard |

Austenitic Steel: |

|

TP304, TP304L, TP304H, TP304N, TP310S, TP316, TP316L, TP316Ti, TP316H, TP317, TP317L, TP321, TP321H, TP347, TP347H,904L… |

|

|

Duplex Steel: |

|

|

S32101, S32205, S31803, S32304, S32750, S32760 |

|

|

Others:TP405,TP409, TP410, TP430, TP439,... |

|

|

European Standard |

1.4301, 1.4307, 1.4948, 1.4541,1.4878, 1.4550, 1.4401, 1.4404, 1.4571, 1.4438, 1.4841, 1.4845, 1.4539, 1.4162, 1.4462, 1.4362, 1.4410, 1.4501 |

ASTMA213 size tolerance chart

|

Size Tolerance |

||||

|

Tube Kinds |

SA213 OD(D) |

SA213 Thickness(S) |

||

|

OD(mm) |

OD Tolerance(mm) |

OD(mm) |

Thickness Tolerance(mm) |

|

|

Hot Rolled |

=101.6 |

+0.4~-0.8 |

76~168.3 |

+28%~0 |

|

>101.6~168.3 |

+0.4~-1.2 |

|||

|

Cold Drawn |

<25.4 |

0.1 |

=38.1 |

+20%~0 |

|

25.4~38.1 |

0.15 |

|||

|

>38.1~<50.8 |

0.2 |

>38.1 |

+22%~0 |

|

|

50.8~<63.5 |

0.25 |

|||

|

63.5~<76.2 |

0.3 |

|||

|

76.2~101.6 |

0.38 |

|||

Size Range

|

Production |

Outside Diameter |

Wall Thickness |

|

Heat Exchanger Tube |

6.00mm -203.2mm |

0.5mm - 21mm |

Final Finishing

Solution Annealed & Pickled/Bright Annealed.

Standard

A 262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A 941 Terminology Relating to Steel, Stainless Steel, Related Alloys and Ferroalloys

A 1016/A 1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

E 112 Test Methods for Determining Average Grain Size

E 527 Practice for Numbering Metals and Alloys

SAE J1086 Practice for Numbering Metals and Alloys

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

One of our Service--Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM A213 TP304 SEAMLESS 19.05x 1.65*6000MM HEAT NO. 2023121205A15