| Ni | Al | C | Fe | Mn | Si | Ti | S | Cu |

|

≥63.00 |

2.30-3.15 |

≤0.18 |

≤2.00 |

≤1.50 |

≤0.50 |

0.35-0.85 |

≤0.010 |

27.00-33.00 |

Monel K500 /UNS N05500/ 2.4375Chemical Composition

Monel K500 /UNS N05500/ 2.4375 Characteristics

Corrosion Resistance: Monel K500 exhibits excellent corrosion resistance in various environments, including marine and chemical settings.

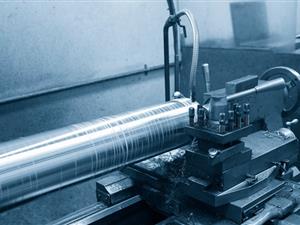

Mechanical Properties: It maintains its mechanical strength even at sub-zero temperatures and up to approximately 480°C.

Non-Magnetic: Monel K500 is non-magnetic, making it suitable for applications where magnetic interference is a concern.

Monel K500 /UNS N05500/ 2.4375 Applications

Marine: Chains, cables, propeller shafts, and other components for marine service.

Chemical Processing: Pump and valve components, as well as other equipment in chemical plants.

Pulp and Paper Production: Doctor blades, scrapers, and other parts.

Oil and Gas: Drill collars, pump shafts, impellers, non-magnetic housings, safety lifts, and valves.

Electronics: Sensors and other electronic components

Monel K500 /UNS N05500/ 2.4375 Material Summary

MONEL® alloy K-500 (UNS N05500/ W.Nr. 2.4375) is a nickel-copper alloy which combines the excellent corrosion resistance of MONEL alloy 400 with the added advantages of greater strength and hardness. The increased properties are obtained by adding aluminum and titanium to the nickel-copper base, and by heating under controlled conditions so that submicroscopic particles of Ni3 (Ti, Al) are precipitated throughout the matrix. The thermal processing used to effect precipitation is commonly called age hardening or aging. The composition of the alloy is given in Table 1. Typical applications for MONEL alloy K-500 products are chains and cables, fasteners and springs for marine service; pump and valve components for chemical processing; doctor blades and scrapers for pulp processing in paper production; oil well drill collars and instruments, pump shafts and impellers, non-magnetic housings, safety lifts and valves for oil and gas production; and sensors and other electronic components.