|

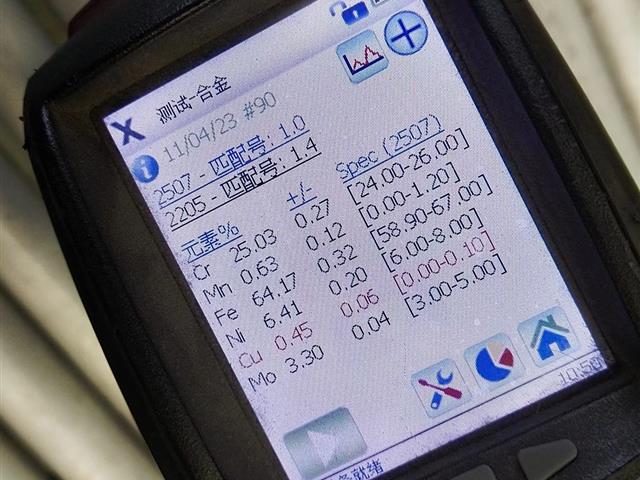

Grade |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

N |

Cu |

|

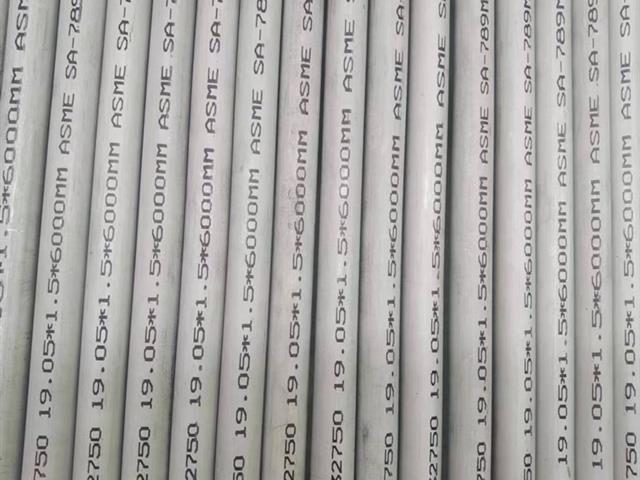

S32750 |

≤0.03 |

≤1.20 |

≤0.035 |

≤0.002 |

≤0.80 |

6.00-8.00 |

24.00-26.00 |

3.00-5.00 |

0.24-0.32 |

≤0.50 |

NOTE: PREN:Cr+3.3*Mo+16*N≥41